how to draw a retaining wall in civil 3d

Retaining walls are as the name suggests any wall that is designed to retain whatsoever textile. The material could be world, water, anything else that needs to be retained. A common case of a retaining wall in everyday life is basement walls, swimming pool walls, and landscape walls.

Before we discuss how to design retaining walls, I desire yous to lookout a simple simply excellent video of how the soil fails behind the retaining wall. The video is courtesy of the British Geological Survey.

This video perfectly shows the failure plane that forms at an bending backside the wall. In this video the soil backside the wall is granular soil. It besides emphasizes that what we do on newspaper is not just a math problem, it is actually a structure that volition be built and intendance should be given every bit to how best to blueprint information technology to preclude failure.

Isaac's Notes:

Today'due south post is a invitee post done by a friend, RG Spaulding, PE over at StructuralCE. She is a nifty structural engineer that has designed buildings, bridges, power plants, and more throughout the land. Her consummate bio can be found below this ballsy postal service. I'd dearest to take more than civil engineer invitee posts on the site to assistance expand on topics that you find interesting! If you accept any feedback, or would like to guest mail service yourself don't hesitate to contact me at [email protected] or on the Contact Page, and go support RG!

More...

Types of Retaining Walls

Here are the types of retaining walls that are build:

- Gravity Walls

- Cantilever Walls

- Counterfort Walls

- Tieback Walls

- Drilled Pier Walls

- Soldier Pile Walls

Of the above, Cantilever retaining wall, Tieback walls, Driller Pier walls and Solider pile walls are the about normally engineered walls. Gravity walls are mainly used for shorter landscaping type of walls equally it becomes less efficient for taller walls.

The main difference between cantilever retaining walls and the other walls mentioned is the way the foundation is designed. Necktie dorsum walls are completely dissimilar retaining walls and rely on pre-stress in ties that concur back the wall thereby retaining the soil.

Before one can pattern retaining walls, a little understanding in soil mechanics is essential.

Soil Parameters Needed

Soil mechanics and Assumptions: In guild to pattern a retaining wall, understanding the soil behavior is critical. The design engineer needs to know some bones soil parameters.

Soil Parameters needed:

- Soil Type (Granular of Cohesive)

- Unit of measurement Weight

- Angle of Friction

- Cohesion

What is cohesion? It is the bounden ability of soil. According to OSHA.gov, cohesive soils is a soil with high clay content. It is plastic when moist merely becomes hard to break when dry. When dry, cohesive soils can exist excavated with nearly vertical slopes. Good example of cohesive soil is clay.

Granular soils are opposite to cohesive soils. The bending of internal friction plays a major function in granular soils since their cohesion value is zero. Case of granular soil is sand. Below is an image of granular soils and above is a cut in dirt.

A Geotech is Your Best Friend

The Geotech usually takes samples of the soil over which a structure is to be built and gives the results of the type of soil that is nowadays at the site. One of the tests that Geotech uses to observe out the angle of internal friction of the soil is a Direct shear examination.

Please lookout man the following video of directly shear exam courtesy of Carleton Academy.

A Geotech will be your best friend when it comes to designing retaining walls. With a bones agreement of soil backdrop and help of a reliable Geotech, you can go about of the data you need to design retaining walls. Choosing a Geotech firm will depend on how you are designing your wall. Some Geotech firms are geared towards "building design" and some firms are geared towards "bridge blueprint".

Even though both Geotechs will give y'all what you need for design, getting the values that can be applied in your process volition be much easier if yous know how and which codes y'all are designing the walls for. Building codes like IBC (International Building code) or local codes similar CBS (California Edifice code) are very different than Bridge codes like AASHTO (American Association of Pike and Transportation Officials).

For instance, within the building design guidelines, the geotech will give, commanded soil pressures, skin friction, active and passive pressures and end bearing values and skin friction values for the foundation or piles if used.

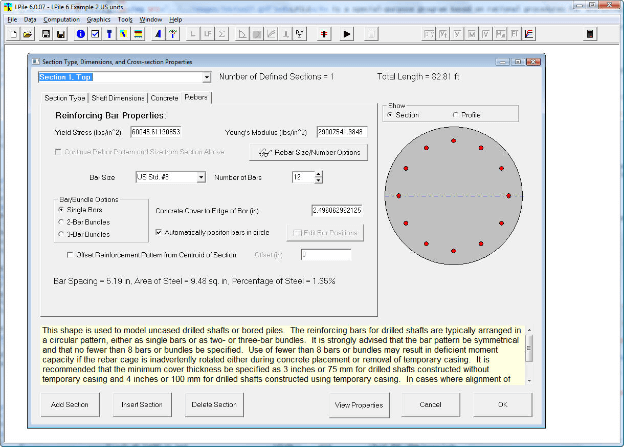

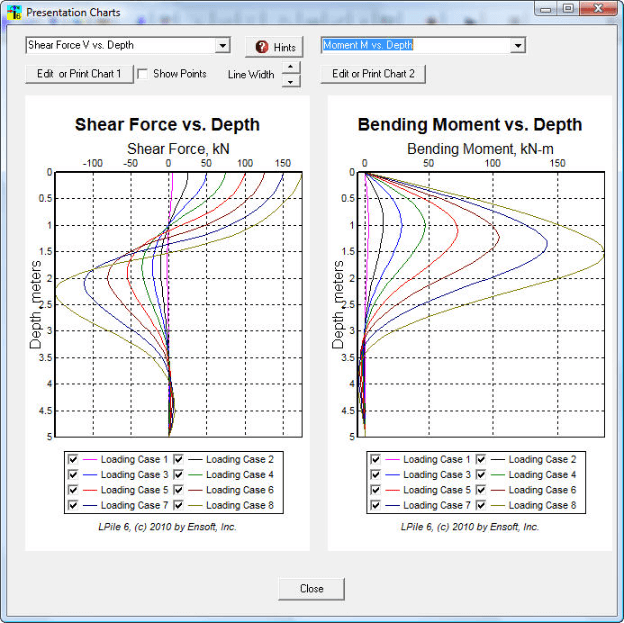

A business firm geared towards the span design manufacture will give values of soil layers and properties of diverse soil layers (LPile values - LPile is a software program which is used to design pile foundations by modelling the various layers of soil). Here is a sample of various soil layers that y'all would expect to see in the Geotech's report.

Then y'all ask, why would I need these layer values?

Yous would need these values if you cannot make your cantilever retaining wall work with the standard foundation because it gets too uneconomical to accept such a big ground or if there are utility lines in the way that would prevent you from existence able to build a big foundation.

Situations like these volition require your walls to be supported by piles at certain intervals. In society to design these piles y'all would need the various soil layers that the pile would be driven or drilled through.

For building codes, most of the fourth dimension, design is elastic and you can directly calculate the elastic section properties and input them in any pile software program. I am using Lpile here because that is the program I am familiar with. In LPile, instead of rubberband section properties, one can also input the cracked department properties for seismic pattern cases.

Here are a few screenshots of the LPile program courtesy of Ensoft Inc.

And then when does one know what code to blueprint these walls to? Building or Span? If these walls are retaining soil that holds upwardly a roadway or in the right of way of a highway and then your wall would come up under the jurisdiction of transportation safety officials and would demand to be designed for AASHTO load combinations.

If that is not the case, then these walls would fall under the building code. Most of the time what is not discussed in standard textbooks is that most of these walls have fences on meridian or in case of walls holding up the soil that supports the roadway, then in that location are barriers or guardrails on top of these walls.

So there are additional moments on the wall due to the fence or bulwark which tin impact the design of the walls. Have yous ever seen a crash test video? It will blow your mind away. Well, in case you haven't watched one, please take a await at the following. These barriers on top of walls transmit enormous forces from crash loads. This video is courtesy of Texas A&M Transportation Constitute. Check it out:

In this video yous can see that in that location is a bulwark on meridian of a MSE retaining wall (Mechanically Stabilized Globe retaining walls), where soil is built upward with reinforcing systems. This is slightly different than cantilever walls. But I merely want to show yous the possibility of enormous amount of bear upon forces that could exist transferred if at that place is a barrier on top of your wall.

This is another classic reason we take various types of retaining walls. I cannot imagine designing a cantilever retaining wall arrangement with forces from barriers. It would have to be pretty hefty and uneconomical.

So when an engineer is designing the walls, he/she has to accept into business relationship all kinds of loads the walls will be subjected to. There are many different types of retaining walls to arrange the loading and soil conditions and obstructions in the way and the engineer needs to discuss with the clients the pros and cons of using a item system of wall and steer them in the right management.

If the wall falls under the jurisdiction of highway so yous don't have to do much convincing. Transportation authorities like CALTRANS (California Department of Transportation) or your regional transportation government have well documented free resources available on their websites equally to what works in a sure situation.

Cantilever Retaining Wall

In this section nosotros will take a unproblematic cantilever retaining wall and discuss the concept of how they are afflicted by the loads and how yous accept to pattern them to resist these loads that they are subjected to.

What is a cantilever retaining wall? Information technology is a wall that acts like a cantilever stock-still at the bottom foundation. Here is a sketch of cantilever retaining wall and for the sake of agreement the basics lets assume an imaginary superman pushing the wall with all his strength.

Find that if he was non standing on the foundation or if the foundation was very short, then he could both push button it or topple it over. Pushing forcefulness is represented by the left pointing arrow and toppling is represented by the curved pointer. But because he is standing on portion of the foundation and the foundation is large, he will accept some difficulty making the wall topple.

The forces shown in Yellow and Orange are the forces that will naturally cause the wall to slide (button) and overturn (topple). The force shown is yellow color is from soil pressure and the forces shown in orange colour is from live load surcharge.

Soil pressure can be "agile" soil pressure or "At-remainder" soil pressure. So what is the deviation betwixt the "active" and "at-rest" soil pressure and how tin can you lot tell which pressure level you should blueprint for?

You should always refer to the recommendations given by the soils engineer. When the wall is flexible (pregnant if the peak of the wall rotates past 0.001 to 0.003 radians or if the top of the wall deflects at the range of 0.001 h to 0.003 h where "h" is the height of the Retaining wall, and then the wall deflects and moves away enough from the soil retained that the horizontal soil pressure decreases to the "active" pressure levels.

You lot should never presume that walls are always designed for agile pressure. If the wall is as well potent then you will exist underestimating the soil pressure that the wall is subjected to. "At-rest" force per unit area is typically greater than "active" pressure.

If there is a roadway or buildings near by to the retaining wall and so the wall will also be subjected to additional pressure called the Live load surcharge. This is shown in orange color in the sketch above. If there is any buildings or structures close to the retaining walls and so the soils engineer volition also recommend the loads coming from the foundation of those structures that the walls have to be designed for.

So what prevents these walls from being pushed and toppled?

Well, see the small blue truncated triangle on the left side? That is the passive pressure.

Passive pressure (in pcf) is usually pretty large only notice that the area of the actual construction that presses against the soil is pretty small so in reality the power of passive pressure solitary to resist these forces is unrealistic.

So what else helps maintain the stability of the wall?

The friction forcefulness between the bottom of the foundation and soil plays a big part in resisting this sliding strength. In virtually text books coefficient of friction between soil and foundation is taken a 0.v which is a relatively loftier number.

In reality a lot of soils engineers ascertain this value to exist much less than that. In one case again soils engineers play a big role in design of the retaining walls and often times they will not permit the design engineer add the effects of 100% passive and 100% friction together. Ane additional particular to proceed in mind during pattern is that there is greater friction if the weight of the structure is large and so if you are trying to blueprint the nigh efficient department it will come back to give yous problems in counteracting sliding forces.

Once your design takes care of overturning and sliding, the 3rd affair you have to check for is to make sure that the soil underneath the foundation can really accept these additional stresses. The soil fill underneath the foundation is rated for a sure amount of allowable bearing pressure. Run across the paradigm beneath on how these overturning forces bear on the soil underneath the foundation.

In Instance i, there is no eccentricity and hence the soil under the footing is uniformly loaded. fmax has to be less than Allowable bearing capacity.

In Case ii, there is Moment that causes eccentric loading on the ground. As long equally the eccentricity e<B/half dozen, and fmax is less than allowable bearing capacity the footing size should be adequate.

In Case 3, the moment is and then big that the eccentricity of the footing is outside of the middle third of the basis or in other words e>B/6. What this indicates is that the basis size is not efficiently used. fmax should over again be less than the allowable bearing chapters but basis size can be adjusted to make the maximum apply of it.

When in whatsoever of the higher up cases fmax is greater than the bearing chapters of the soil, then the soil underneath the footing fails. This should be avoided at all costs.

Another of import topic in the blueprint of retaining walls is actual drainage details. Most retaining wall failures are caused due to improper drainage details.

Imagine what happens if the soil on the right side of the wall in the moving-picture show to a higher place is water-logged due to drains clogged or no drains at all? There is boosted force per unit area on the wall due to h2o. The density of water is 62.four pcf which is quite a big additional pressure level on the wall.

If the meridian of soil to exist retained above the footing is "h". Information technology is good practice to design the wall to be 6" taller than the soil to be retained. The height of the footing also has to exist a minimum of 12" beneath the tiptop of soil on the toe side (side that shows signal "A"). In order for y'all to pictorially see what additional forces the wall could potentially be subjected to please see sketch below.

When at that place is an convulsion the wedge of soil above the failure aeroplane will cause boosted shear on the wall. This is an changed triangle with larger forces acting on the meridian of the wall which means the moments due to seismic forces (inverse triangular force) on the base of the footing can be a huge addition to the moments due to the active force per unit area. The soils engineer will really give you the value of the seismic forces that human action on the wall.

In order to calculate the forces that crusade the wall to overturn, moment and shear are calculated near the signal "A" in the diagram above. Just from ascertainment, you tin can tell that the passive pressure is very minor force to annul the active forces causing the ground to overturn and slide.

Your job as an engineer is to brand sure that y'all design the wall and foundation to be potent plenty to resist these forces shown past the ruddy arrows. Designing retaining walls is an iterative process. Sometimes you are and so shut to your pattern working just not quite enough for sliding. In those instances yous have to compare costs to meet what is the all-time culling.

To add a shear key nether the footing to engage more than passive pressure or simply make the ground big enough to increase the frictional forces? It is a trial and error process, just take into account what it volition price not just for materials just besides labor to accept to cascade a shear key (additional trenching, boosted concrete, boosted steel).

I hate to say, nosotros are nonetheless merely scratching the surface of retaining wall design. At that place is and then much to talk about. Here is a video of retaining wall collapse in Baltimore, Maryland. After you watch the video, you can also read the blog post written past Dr. Dave Petley nigh this item retaining wall plummet. I believe this particular collapse was due to heavy rains and lack of adequate drainage and the wall itself seems nether designed for the loads that it was subjected to.

It is good that no 1 got hurt during that collapse.

When Does A Cantilever Wall Not Work?

There are instances where these cantilever retaining walls cannot be used. Say for instance y'all are actually close to property lines or if there is a buried pipe underneath that yous notice when you actually start doing site surveys.

Maybe there is a building or tower side by side to the wall and the foundation of that structure will interfere with the foundation of retaining walls, etc. There are many reason why cantilever walls might not work. In these situations, there are other options. Some of these options are tieback walls, drilled pier walls, soldier pile walls, etc. Allow's talk over a few.

Tieback Walls

What is a tieback wall?

It is a wall that is really property the soil in place with a network of ties (prestressing tendons). Ties are placed in a grid mode and usually at a 15 degree angle and are positioned to miss the abutment piles. Ties are bang-up option when the soil to be contained is nearly an abutment of a bridge where the spacing is so restricted that huge foundations are impossible.

Run into sketch below:

Below sketch shows a close up of what makes the ties (image courtesy of Caltrans).

Each tie has the following components:

Prestressing steel: Transfers the wall reactions to the anchor zone in the soil through the bonded length

Bond length: This is the zone where the steel is inside the grout seedling that is fixed and transfers the load from the steel to the surrounding soil. This is also called the Ballast zone. This bonded length has to extend by the failure plane of the soil.

Unbonded length: This is the portion of the steel that is free to elastically elongate and thereby transfer the resisting force from the bonded area to the wall.

Wall anchorage: This usually is at the wall element. Has a plate and ballast head which is a threaded nut and allows the steel to be prestressed and locked off.

Grou t: Provided a medium through which load gets transferred to the soil and likewise protects the pre-stressing steel from corrosion.

Because these tendons are angled, there will exist a horizontal and vertical component of the soil reactions. There is also boosted vertical load due to the expressionless weight of the wall. So, for stability of the wall, the blueprint engineer has to take into account both these forces.

Tieback walls are comparatively much simpler to design than the other types of retaining walls.

Drilled Pier Walls

These are walls that rest on top of a cap beam or form axle which is in turn supported by a series of drilled piers that are spaced uniformly. The wall portion of the pattern is similar to the cantilever retaining wall (the wall is fixed at the lesser to the form beam) merely in add-on to that the engineer has to brand sure that the class beam is sufficiently designed to take the moments and shears from the wall and pass it onto the piers.

The grade beam will exist subjected to some major torsion which has to be additionally checked. The drilled piers are so designed using a programme called LPile where all the dissimilar soil layers and piles are modeled and subjected to the moments, shears and axial loads from the walls.

The pile holes are drilled using an auger which is a huge drill. All the soil inside the hole is removed and then the rebar cage is lowered into it so the physical is placed.For anyone who would like to see an animation of the many unlike types of piles and their methods of construction, hither are some Youtube videos (courtesy of Hayward Baker Inc).

Here is an actual real life drilling video courtesy of Pearson Drilling Inc. You can run across in the video beneath that the site conditions are wet and so they are using a temporary steel casing in lodge to prevent caving in of the soil and then insert the rebar cage and pour the concrete. Once physical is poured the temporary steel casing is removed.

The various types of defects that can happen in CIDH (Bandage in drilled hole) piles is that the walls of the hole tin cavern in while removing casing, or the concrete separates and forms pockets of air holes. There might be air pocket in the existing soil adjacent to the pile that is being drilled that is not visible but would cease upwardly leaking the poured concrete out of the drilled pier.

Soldier Pile Walls

A soldier pile wall is similar to driller pier wall with the exception of a broad "W " or "H" section is used in the pile instead of rebar cage. Wood lagging or woods sleepers spans between the soldier piles and temporarily concord upwards the soil until the permanent wall is installed.

The permanent wall could be either shorcrete or cast in place wall. The wood lagging temporarily handles the soil pressure level until the concrete walls cure and become constructive. The Westward or H sections are placed into a drilled hole and checked for plumbness and then structural physical fill is placed.

The timber lagging is placed every bit the soil gets excavated in stages so the rebar cage for the wall is placed with the woods lagging acting equally a physical course. Near cases the wall is actually a shotcrete wall where concrete is pumped by a hose. The metal studs that are welded to the flange of the H section will structurally tie the wall to the soldier pile.

In some instances (depending on the soil atmospheric condition) the H department is driven straight into the ground instead of placing inside a drilled hole and filled with concrete. In virtually cases this would just be a temporary status.

The following video (courtesy of Piling & Civil Australia) shows animation of how the timber lagging goes in stages as the soil gets excavated but this blitheness does non show the concrete placed in the drilled hole.

Sometimes these soldier pile walls are combined with ties at the top to help maintain a smaller H department. Ties basically will reduce the cantilever length of the wall thereby reducing the moments and shears on the H section.

The side by side video shows an actual placement of the H department inside the drilled hole and concrete placed into it. Courtesy of Helitech Civil Structure Division

Conclusion

I hope you constitute this post useful. Cheers to Isaac for letting me come here as a guest blogger and share some of what I know with all of you. If y'all liked information technology, please share it with people who may be interested in it.

I hope to add together the actual detailed design process of all these retaining walls into my class I'g creating. If yous desire to larn more than about information technology you should check it out. You can learn something new as well every bit obtain continuing educational activity credits!

As always, thanks for reading and please visit me at StructuralCE.

Bio: RG Spaulding, PE

Hello, My proper noun is Ramya G. Spaulding. I go past RG Spaulding. I am a licensed ceremonious engineer in the State of California and State of Due south Carolina. I got my MS in ceremonious with Structural Engineering science accent from Clemson University. Here is my LinkedIn Contour.

I have over 20 years feel designing structures(Buildings, Bridges, Industrial structures, Power plants that were installed all over the world). New work opportunities and family commitments have resulted in my moving all the style from due east coast to westward declension with a stop in the middle. As a result, I accept been fortunate to learn many new things every time I switched jobs. This kept work interesting and immune me to learn a multifariousness of designs and construction techniques.

Then now after 20 years, I have decided to develop courses online then other young engineers starting out or engineers looking for standing didactics credits can detect my feel useful.

Source: https://civilengineeringacademy.com/the-four-different-types-of-retaining-walls-that-every-civil-engineer-must-know/

Post a Comment for "how to draw a retaining wall in civil 3d"